OECD 2024 Insights on Responsible Textile Supply Chains

OECD 2024 Insights on Responsible Textile Supply Chains

OECD 2024 Insights on Responsible Textile Supply Chains

Written By:

Mark Kaplan

Feb 2, 2026

Mark Kaplan

Feb 2, 2026

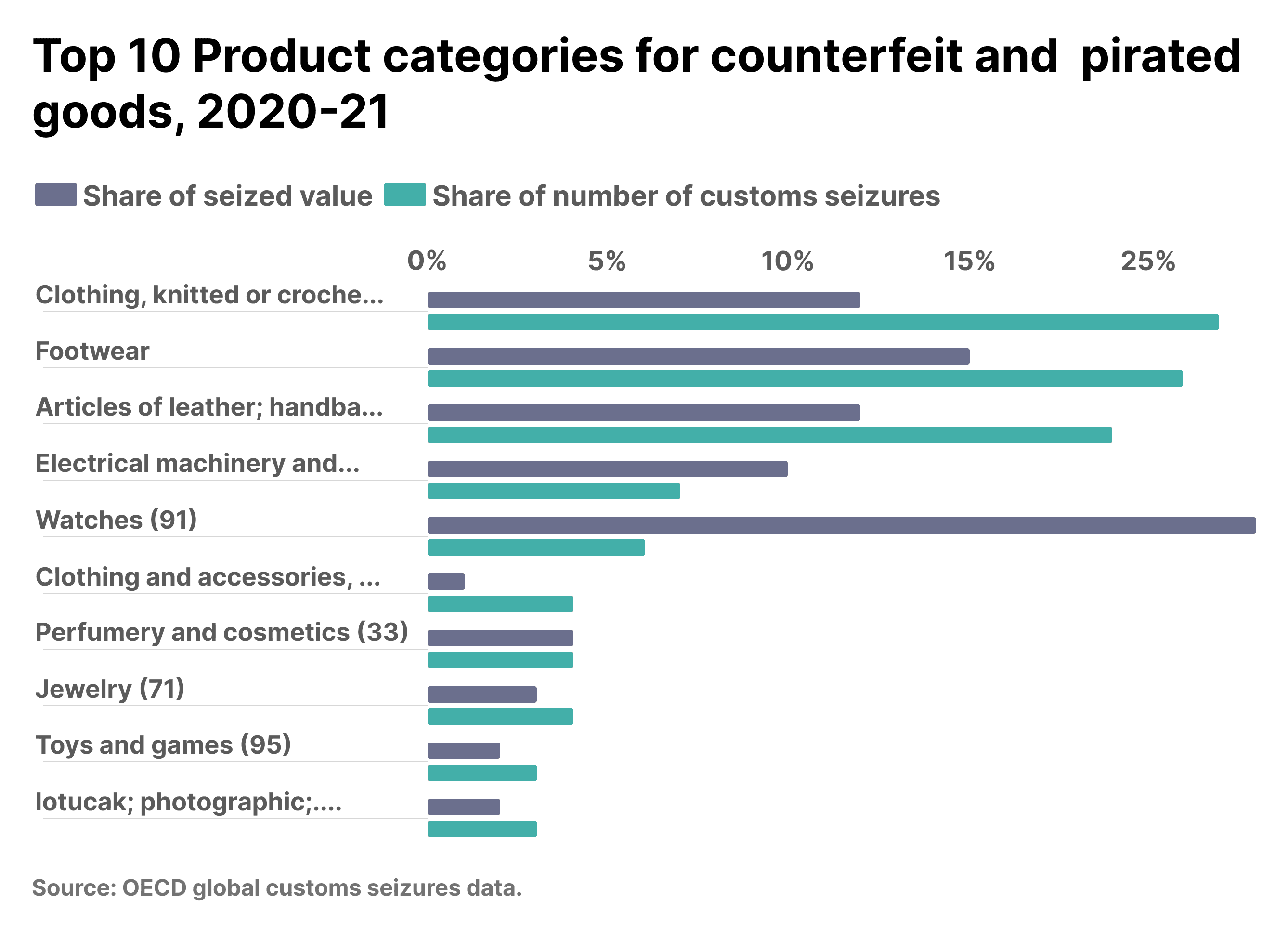

Global supply chains in the garment and footwear industry face rising pressure from regulators, investors, and consumers to deliver on sustainability, transparency, and human rights targets. According to OECD customs seizure data from 2020-2021, textile related industries are the top 3 product categories for counterfeit and pirated goods.

The OECD’s 2024 report, “From Fakes to Forced Labour,” underscores how weak traceability and opaque sourcing enable both counterfeit goods and labor abuses to persist. The report calls for integrating due diligence obligations with product traceability requirements to break silos between market surveillance, labor rights enforcement, and corporate accountability. Aligning trade and sustainability agendas is overdue.

In parallel, the OECD’s Garment and Footwear Sector Due Diligence Guidance (updated in 2023 and still heavily referenced) remains the global benchmark for responsible sourcing. It defines expectations for identifying, mitigating, and accounting for risks in supply chains from labor exploitation to environmental harm. Crucially, it emphasizes the importance of upstream and downstream data flows, collaborative risk-based prioritization, and using leverage effectively.

Standardized, End-to-End Traceability Enables Better Decisions and Trust

Data standardization enables industry to collaborate on risk-based priorities. Standardization provides data consistency and harmonization in data collection, enabling companies to accurately monitor and measure practices. Without standardization, data siloes and proprietary systems will continue to prevent proper due diligence.

Reinforcing these calls to action, the UNECE’s 2024 “Sustainability Pledge” 3-Year Monitoring Report provides a practical blueprint. It analyzes over 100 traceability pledges from global brands, suppliers, and civil society actors. Among its findings:

79% of pledges integrate both traceability and transparency efforts showing growing recognition that these two elements must go hand in hand.

SMEs represent 62% of pledging suppliers/producers/retailers, confirming the urgency of scalable, cost-effective solutions for smaller actors.

Non-financial incentives (like visibility, collaboration, and standardization) are more widely used than financial ones, signaling the power of reputational and partnership drivers in mobilizing change.

Together, these reports form a cohesive roadmap that sees traceability as a strategic lever for risk mitigation, supply chain integrity, and brand trust.

Global markets are demanding that industry leaders are able to answer the “who”, “what”, “where”, “when”, “why” and “how” about their supply chains. Proprietary systems, certification, legacy supply chain mapping and chain of custody tools that do not follow movement of goods have proven insufficient can only answer some of these questions. Meanwhile, end-to-end traceability systems that use interoperable data standards for lot- or serial-level data collection provide a complete picture of the supply chain. In addition to collaboration between stakeholders and inclusive governance, these systems provide industry leaders with the information they need to make informed decisions about their supply chain practices.

Wholechain supports this vision by enabling interoperable, end-to-end traceability for supply chains of any size or complexity, from cotton and leather, to seafood and specialty crops. We help bridge the gap between sustainability goals and operational realities, providing traceability that businesses can leverage to improve practices and mitigate problems across their supply chains . Wholechain is proud to be part of the WWF and Better Food Future led Global Traceability Framework for Beef and Leather in collaboration with IFT, Rever and FAI Farms.

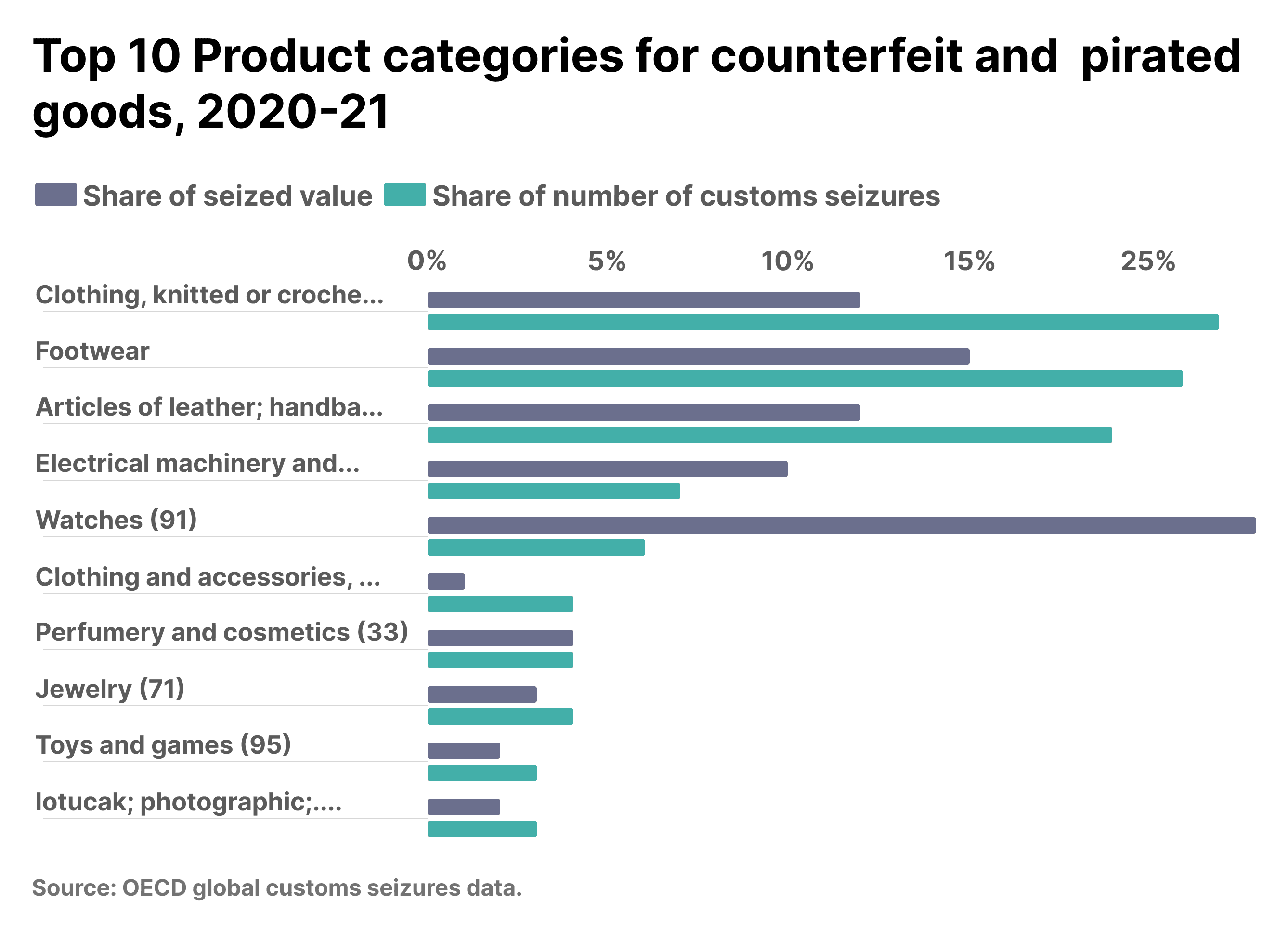

Global supply chains in the garment and footwear industry face rising pressure from regulators, investors, and consumers to deliver on sustainability, transparency, and human rights targets. According to OECD customs seizure data from 2020-2021, textile related industries are the top 3 product categories for counterfeit and pirated goods.

The OECD’s 2024 report, “From Fakes to Forced Labour,” underscores how weak traceability and opaque sourcing enable both counterfeit goods and labor abuses to persist. The report calls for integrating due diligence obligations with product traceability requirements to break silos between market surveillance, labor rights enforcement, and corporate accountability. Aligning trade and sustainability agendas is overdue.

In parallel, the OECD’s Garment and Footwear Sector Due Diligence Guidance (updated in 2023 and still heavily referenced) remains the global benchmark for responsible sourcing. It defines expectations for identifying, mitigating, and accounting for risks in supply chains from labor exploitation to environmental harm. Crucially, it emphasizes the importance of upstream and downstream data flows, collaborative risk-based prioritization, and using leverage effectively.

Standardized, End-to-End Traceability Enables Better Decisions and Trust

Data standardization enables industry to collaborate on risk-based priorities. Standardization provides data consistency and harmonization in data collection, enabling companies to accurately monitor and measure practices. Without standardization, data siloes and proprietary systems will continue to prevent proper due diligence.

Reinforcing these calls to action, the UNECE’s 2024 “Sustainability Pledge” 3-Year Monitoring Report provides a practical blueprint. It analyzes over 100 traceability pledges from global brands, suppliers, and civil society actors. Among its findings:

79% of pledges integrate both traceability and transparency efforts showing growing recognition that these two elements must go hand in hand.

SMEs represent 62% of pledging suppliers/producers/retailers, confirming the urgency of scalable, cost-effective solutions for smaller actors.

Non-financial incentives (like visibility, collaboration, and standardization) are more widely used than financial ones, signaling the power of reputational and partnership drivers in mobilizing change.

Together, these reports form a cohesive roadmap that sees traceability as a strategic lever for risk mitigation, supply chain integrity, and brand trust.

Global markets are demanding that industry leaders are able to answer the “who”, “what”, “where”, “when”, “why” and “how” about their supply chains. Proprietary systems, certification, legacy supply chain mapping and chain of custody tools that do not follow movement of goods have proven insufficient can only answer some of these questions. Meanwhile, end-to-end traceability systems that use interoperable data standards for lot- or serial-level data collection provide a complete picture of the supply chain. In addition to collaboration between stakeholders and inclusive governance, these systems provide industry leaders with the information they need to make informed decisions about their supply chain practices.

Wholechain supports this vision by enabling interoperable, end-to-end traceability for supply chains of any size or complexity, from cotton and leather, to seafood and specialty crops. We help bridge the gap between sustainability goals and operational realities, providing traceability that businesses can leverage to improve practices and mitigate problems across their supply chains . Wholechain is proud to be part of the WWF and Better Food Future led Global Traceability Framework for Beef and Leather in collaboration with IFT, Rever and FAI Farms.

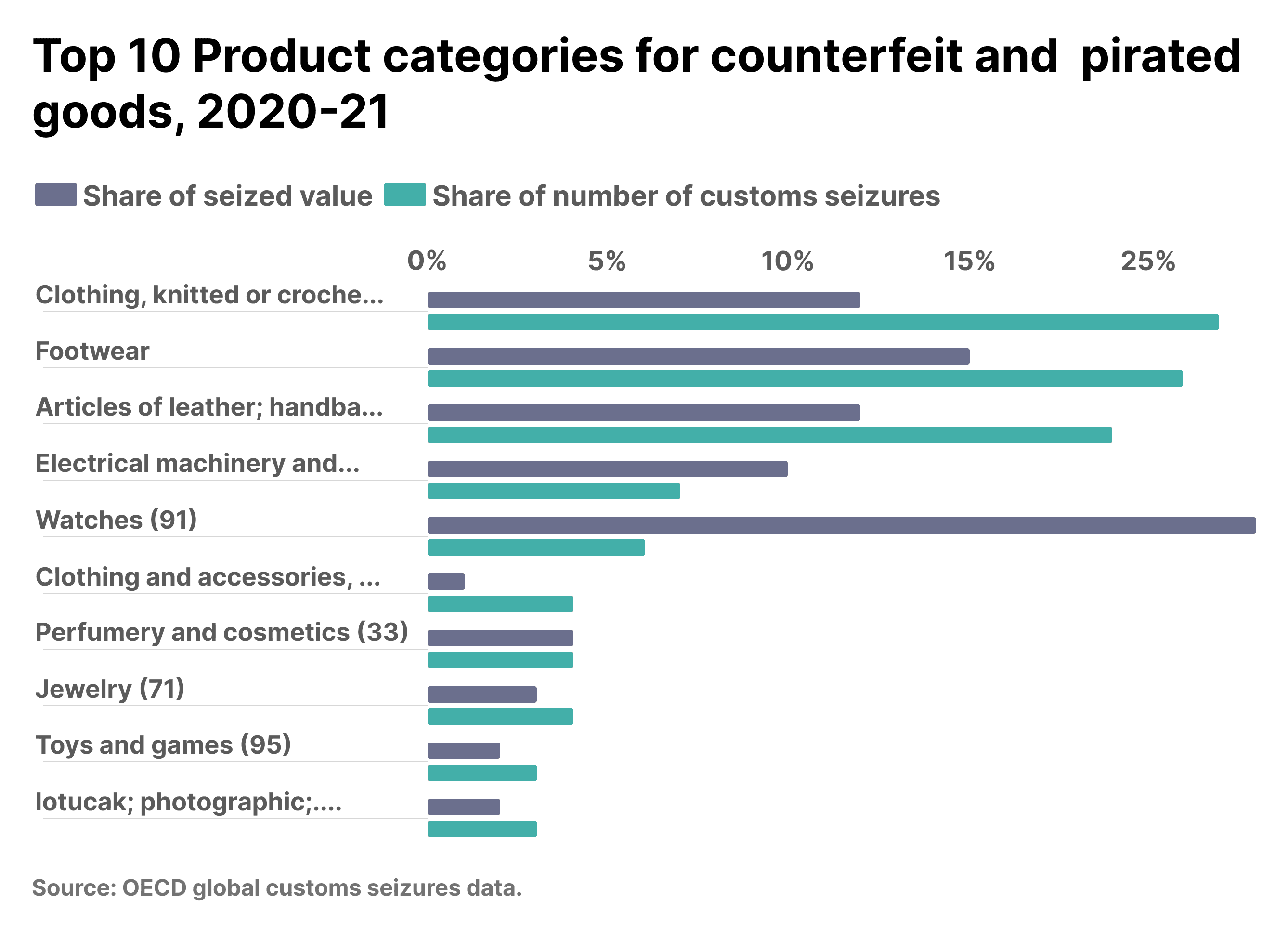

Global supply chains in the garment and footwear industry face rising pressure from regulators, investors, and consumers to deliver on sustainability, transparency, and human rights targets. According to OECD customs seizure data from 2020-2021, textile related industries are the top 3 product categories for counterfeit and pirated goods.

The OECD’s 2024 report, “From Fakes to Forced Labour,” underscores how weak traceability and opaque sourcing enable both counterfeit goods and labor abuses to persist. The report calls for integrating due diligence obligations with product traceability requirements to break silos between market surveillance, labor rights enforcement, and corporate accountability. Aligning trade and sustainability agendas is overdue.

In parallel, the OECD’s Garment and Footwear Sector Due Diligence Guidance (updated in 2023 and still heavily referenced) remains the global benchmark for responsible sourcing. It defines expectations for identifying, mitigating, and accounting for risks in supply chains from labor exploitation to environmental harm. Crucially, it emphasizes the importance of upstream and downstream data flows, collaborative risk-based prioritization, and using leverage effectively.

Standardized, End-to-End Traceability Enables Better Decisions and Trust

Data standardization enables industry to collaborate on risk-based priorities. Standardization provides data consistency and harmonization in data collection, enabling companies to accurately monitor and measure practices. Without standardization, data siloes and proprietary systems will continue to prevent proper due diligence.

Reinforcing these calls to action, the UNECE’s 2024 “Sustainability Pledge” 3-Year Monitoring Report provides a practical blueprint. It analyzes over 100 traceability pledges from global brands, suppliers, and civil society actors. Among its findings:

79% of pledges integrate both traceability and transparency efforts showing growing recognition that these two elements must go hand in hand.

SMEs represent 62% of pledging suppliers/producers/retailers, confirming the urgency of scalable, cost-effective solutions for smaller actors.

Non-financial incentives (like visibility, collaboration, and standardization) are more widely used than financial ones, signaling the power of reputational and partnership drivers in mobilizing change.

Together, these reports form a cohesive roadmap that sees traceability as a strategic lever for risk mitigation, supply chain integrity, and brand trust.

Global markets are demanding that industry leaders are able to answer the “who”, “what”, “where”, “when”, “why” and “how” about their supply chains. Proprietary systems, certification, legacy supply chain mapping and chain of custody tools that do not follow movement of goods have proven insufficient can only answer some of these questions. Meanwhile, end-to-end traceability systems that use interoperable data standards for lot- or serial-level data collection provide a complete picture of the supply chain. In addition to collaboration between stakeholders and inclusive governance, these systems provide industry leaders with the information they need to make informed decisions about their supply chain practices.

Wholechain supports this vision by enabling interoperable, end-to-end traceability for supply chains of any size or complexity, from cotton and leather, to seafood and specialty crops. We help bridge the gap between sustainability goals and operational realities, providing traceability that businesses can leverage to improve practices and mitigate problems across their supply chains . Wholechain is proud to be part of the WWF and Better Food Future led Global Traceability Framework for Beef and Leather in collaboration with IFT, Rever and FAI Farms.

Mark Kaplan

Feb 2, 2026

Want to get started on traceability?

Want to get started on traceability?

Want to get started on traceability?

Explore how traceability works and take your first step in getting started,

simply click the link below.

Explore how traceability works and take your first step in getting started,

simply click the link below.